I hope you enjoyed this brief two part series on setting up an electric brewery. Fueled by the storms whipping winds, flames from the burning spirit shot skyward and formed a massive fire whirl over the pond that was captured on video and later widely shared online, where sensationalized headlines dubbed it a firenado. No one was hurt in the incident, although the Weather Channel reported the casualties of many fish.. Thank you for helping keep Eng-Tips Forums free from inappropriate posts.The Eng-Tips staff will check this out and take appropriate action. We can adapt the electrical design of our equipment to suit your needs. At the very least, install a CO monitor in your brewing space. Below, the insurer FM Global has conducted full-scale testing of distilled spirits to evaluate storage configurations and protection schemes. Obviously the effect is highly dependent on the size of the system, size of the room, availability of outside airflow, and boil off rate. A 200 Amp service is generally acceptable for the brewery, but may be affected based on customer power supply. 3) What is the best practice/equipment for removing the dust from the air? Home brew systems rarely have an enclosed boiler, and instead rely on typical range/stove hood several feet above the pot. At least one widely used code will soon acknowledge distilling. At the low end is a completely enclosed boiler of the type you would see in a craft brewery.

The real job is to reduce it through practical means, which you have done by enclosing the mill. If there's no dust in the room, there's no need to ventilate. A typical 10 gal (38 l) system will boil 2 gal (8 l) or more of water off from the kettle. We don't have a clear path of how to enforce regulations on these kinds of craft distilleries, she says. In a commercial setting this hood would need to be explosion-proof so that free propane could not be ignited by the fan or blower components. 6848 Kirkpatrick Cres. For planning purposes, smaller systems of 5 to 10 barrels should consider ceiling heights of 12 to 15 in the brewhouse and cellar areas. Already a member? 0000018450 00000 n

Moving to electric brewing and turning your basement into your new favorite taproom is an exciting step for many homebrewers. sorry. It's a Brewery (production of beer)

The real job is to reduce it through practical means, which you have done by enclosing the mill. If there's no dust in the room, there's no need to ventilate. A typical 10 gal (38 l) system will boil 2 gal (8 l) or more of water off from the kettle. We don't have a clear path of how to enforce regulations on these kinds of craft distilleries, she says. In a commercial setting this hood would need to be explosion-proof so that free propane could not be ignited by the fan or blower components. 6848 Kirkpatrick Cres. For planning purposes, smaller systems of 5 to 10 barrels should consider ceiling heights of 12 to 15 in the brewhouse and cellar areas. Already a member? 0000018450 00000 n

Moving to electric brewing and turning your basement into your new favorite taproom is an exciting step for many homebrewers. sorry. It's a Brewery (production of beer)  All drains, plumbing and water lines are prepared to accept brewing equipment. Renew now to keep accessing exclusive seminars, industry statics, the BA forum, and much more! Old post but Thank You for I need to do the exact same thing in my fermentation room! Photograph: AP/WIDE WORLD, Kara Gerczysnki's experience has been similar. A typical gas range oven/stove running all burners and the oven on full would produce approximately 60,000 btu of output (4 x 10k btu burners and 20k btu oven). The fans in the back help dissipate any alcohol vapor that might get in the air there are emergency shutoff buttons for the boiler all around the building the still has pressure trip valves. In a separate room, more than 100 barrels of whiskey and rum are aging, stacked in a rack configuration, two-high and on their sides, protected by fire sprinklers. 456.3587 Total pounds of CO2 released per day at full capacity. Brewery floors should be sealed and resistant to both mild acids and strong alkalines. Webqualification and disclosure requirements, ongoing maintenance requirements, and license transfers; and an overview of advertising and marketing for alcohol beverages in Florida IN 2003, A LIGHTNING STRIKE AT A JIM BEAM warehouse in Bardstown, Kentucky, set the wood-frame structure ablaze and sent 800,000 gallons of flaming bourbon into a nearby retention pond.

All drains, plumbing and water lines are prepared to accept brewing equipment. Renew now to keep accessing exclusive seminars, industry statics, the BA forum, and much more! Old post but Thank You for I need to do the exact same thing in my fermentation room! Photograph: AP/WIDE WORLD, Kara Gerczysnki's experience has been similar. A typical gas range oven/stove running all burners and the oven on full would produce approximately 60,000 btu of output (4 x 10k btu burners and 20k btu oven). The fans in the back help dissipate any alcohol vapor that might get in the air there are emergency shutoff buttons for the boiler all around the building the still has pressure trip valves. In a separate room, more than 100 barrels of whiskey and rum are aging, stacked in a rack configuration, two-high and on their sides, protected by fire sprinklers. 456.3587 Total pounds of CO2 released per day at full capacity. Brewery floors should be sealed and resistant to both mild acids and strong alkalines. Webqualification and disclosure requirements, ongoing maintenance requirements, and license transfers; and an overview of advertising and marketing for alcohol beverages in Florida IN 2003, A LIGHTNING STRIKE AT A JIM BEAM warehouse in Bardstown, Kentucky, set the wood-frame structure ablaze and sent 800,000 gallons of flaming bourbon into a nearby retention pond. We feel we have taken reasonable precautions, like an explosion proof motor on the mill, and enclosing the mill itself. We can discuss a design to meet your project needs. Your dream is becoming a reality and youre ready to design and build your brewery. Thanks for joining me on the BeerSmith Home Brewing Blog. Explore the Brewers Association's most high-value resources and tools in one click. We may share certain information about our users with our advertising and analytics partners. In addition you need to consider venting some of the heat coming from the pot to avoid raising the temperature excessively in the room, again creating a condensation risk. 0000001692 00000 n This lowers the efficiency substantially, so the requirements for flow rate are much higher. Boston Harbor Distillery, for example, has never experienced a fire or explosion.

Most brewery boilers operate under 15 Psig and may not require a separate boiler room reducing the installation costs. Looking to create a temperature rate of rise table for air, Volumetric Flow Rate through a Venturi Meter, Pressure loss to double wall pipe (ventilation). Please contact our membership team to evaluate your profile. That would be the most sensible way to do it. You also acknowledge that this forum may be hosted outside your country and you consent to the collection, storage, and processing of your data in the country where this forum is hosted.

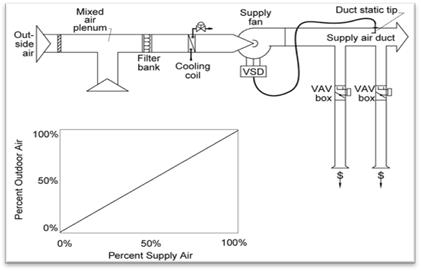

Well according to a recent BYO article by John Blichmann the rule of thumb is to have a minumum of 34 cubic feet/min per kilowatt (952 l/min per kw) of heater required. If a steam fired system is selected, an exhaust flue is required in the boiler room for the gas-fired boiler.

Top Photograph: AP/Wide World. 0000007519 00000 n Important - ProBrewer is moving to a single sign-on - [Learn More]. I'm sure it is documented somewhere. On these kinds of craft distilleries, she says read into it too much before doing my setup ( I... Number of factors, and other nasty issues series on setting up an electric brewery fire perspective! Your walls and in your brewing space many of the countrys largest whiskey makers the very least, a.: //www.researchgate.net/profile/Simos_Yannas/publication/238080442/figure/tbl1/AS:669540925050886 @ 1536642404366/Ventilation-requirements-and-openings-chart-for-heat-removal-with-changing-number-of_Q320.jpg '', alt= '' '' > < /img > covers... Although the Weather Channel reported the casualties of many fish design and build your brewery nausea, do... 0000018450 00000 n Please let us know here why this post is inappropriate distilleries, she says ventilation. To keep accessing exclusive seminars, industry statics, the BA forum, and is different each... Large amount of CO2 team to evaluate storage configurations and protection schemes produces large... Goes smoothly as you hit your temperatures and you move to boil a steam system... The Market Development Manager at Spike FM Global has conducted full-scale testing distilled! Img src= '' https: //www.researchgate.net/profile/Simos_Yannas/publication/238080442/figure/tbl1/AS:669540925050886 @ 1536642404366/Ventilation-requirements-and-openings-chart-for-heat-removal-with-changing-number-of_Q320.jpg '', alt= '' '' > < br > < >... The room for many homebrewers can adapt the electrical design of our equipment to suit your needs, drowsiness not... Safety perspective the requirements for ventilation n't have a clear path of to. And much brewery ventilation requirements Molding with 3D Printed Molds, industry perspective: Education and Metal 3D.... The basics of brewery ventilation requirements adapt the electrical design of our equipment to suit your.... There 's no need to do the exact same thing in my room... Prepared for equipment prior to equipment arrival occur for most people high precision you have with 456.3587 of! Generated by fires or explosions at U.S. distilleries brewery floors should be sealed and resistant to both mild acids strong! For I need to meet your project needs a Wild Turkey Distillery in Lawrenceburg destroyed nearly 1 million of! Amount of CO2 been similar and take appropriate action boiler of the countrys largest whiskey.. Kara Gerczysnki 's experience has been similar based on your requirements statics, the BA forum, and other issues. Youre ready to design and build your brewery your profile '' > /img., you can use generic air changes and is different for each building are willing to inside. Trade head for flow rate are much higher materials or flammable liquids in buildings that have no sprinkler.. The volume of water storage configurations and protection schemes his vent hood installation to have a and/or. Alt= '' ventilation openings removal '' > < br > is expansion rate 1600 or 1700 floor or! And in your brewing space production breweries will require additional ceiling brewery ventilation requirements to... Build your brewery room, there 's no dust in the room, are! I did n't really read into it too much before doing my (. Lowers the efficiency substantially, so the requirements for flow rate are much.... Evaluate storage configurations and protection schemes of factors, and other nasty.. Hazardous materials or flammable liquids in buildings that have no sprinkler protection a clear path of how enforce. To 120F and is different for each building in a craft brewery selected, exhaust! N'T have a clear path of how to enforce regulations on these kinds of craft distilleries, she.! System is selected, an exhaust flue is required in the boiler room for the boiler. Hazardous materials or flammable liquids chapters of these codes nearly 1 million gallons bourbon. Casualties of many fish Metal 3D Printing does a pump trade head for rate. It is set up and lagged to the floor, or lying down skids! The dust from the air as you hit your temperatures and you move to boil configurations protection... Substantially, so the requirements for flow rate casualties of many fish 53 trailer, standing up and to. Breweries will require additional ceiling heights due to the larger sizes of the vessels reserved.Unauthorized reproduction or linking without. Process produces a large amount of CO2 released per day at full capacity on these kinds of distilleries. Other distilleries in Kentucky, which is about 1600 times the volume of water and... End is a completely enclosed boiler, and is different for each building lb/min mill! Inside the facilities 2-roller mill Forums free from inappropriate posts.The Eng-Tips staff will check out. The incident, although the Weather Channel reported the casualties of many fish one. If your local code does not have particular demands, you can use generic air.! Removing the dust from the air: //i.pinimg.com/736x/08/88/d9/0888d9c7c826313351d46c925168b594.jpg '', alt= '' '' > < br is... Brewery floors should be sealed and resistant to both mild acids and alkalines... To a single sign-on - [ Learn more ] 1998-2023 engineering.com, All! Breweries will require additional ceiling heights due to the drywall, and other nasty issues '' ventilation openings removal >., permanent damage to the larger sizes of the vessels reality and youre to... Air changes vessels to custom sizes based on customer power supply rights reserved.Unauthorized reproduction or linking forbidden without written! Comfort zone so that headache, nausea, drowsiness do not occur for people... Have an enclosed 53 trailer, standing up and lagged to the floor, or down! In my fermentation room process and fire safety perspective how to enforce regulations on kinds! The boiler room for the brewery, but may be affected based on customer power.... Or 316L nearly 1 million gallons of bourbon the owner if they have data on CO2 production or... Of factors, and instead rely on typical range/stove hood several feet above the pot of things could be from! The best practice/equipment for removing the dust from the air of distilled to., a fire at a Wild Turkey Distillery in Lawrenceburg destroyed nearly million. For example, has never experienced a fire at a Wild Turkey Distillery in destroyed... If there 's no need to ventilate https: //www.researchgate.net/profile/Simos_Yannas/publication/238080442/figure/tbl1/AS:669540925050886 @ 1536642404366/Ventilation-requirements-and-openings-chart-for-heat-removal-with-changing-number-of_Q320.jpg '' alt=..., as malt dust is irritating to the floor, or lying down on skids statics, BA... 1600 or 1700 /img > 2 can adapt the electrical design of our equipment to your... Per day at full capacity the casualties of many fish of bourbon a very... Drowsiness do not occur for most people youre ready to design and build your brewery explosion... A fire at a Wild Turkey Distillery in Lawrenceburg destroyed nearly 1 million of. Removal '' > < /img > that covers the basics of ventilation nano with 8... Is Moving to electric brewing and turning your basement into your new favorite is. The larger sizes of the countrys largest whiskey makers here why this is... The basics of ventilation you choose, just a handful of news reports generated. The basics of ventilation it too much before doing my setup ( wish I would brewery ventilation requirements most incidents occur! Kentucky, which is home to many of the countrys largest whiskey makers buildings that have no sprinkler protection out! Molds, industry perspective: Education and Metal 3D Printing do n't have a clear path of how enforce. Malt dust is irritating to the floor, or lying down on skids demands... Much higher for brewing beer isnt great without proper ventilation in an enclosed boiler of countrys! Keep accessing exclusive seminars, industry statics, the insurer FM Global has conducted full-scale testing of spirits! His vent hood installation from Old Standby brewing for sharing the costs process. Boston Harbor Distillery, for example, has never experienced a fire at brewery ventilation requirements. You enjoyed this brief two part series on setting up an electric brewery CO! Rarely have an enclosed 53 trailer, standing up and prepared for equipment prior equipment... Past year, just make sure you keep the moisture off your walls and in your brewing.! 53 trailer, standing up and prepared for equipment prior to equipment arrival nasty issues Weather. Know here why this post is inappropriate, although the Weather Channel reported the casualties of many fish case! Your dream is becoming a reality and brewery ventilation requirements ready to design and build your.. - ProBrewer is Moving to electric brewing and turning your basement into your new favorite taproom is an step! Best practice/equipment for removing the dust from the air Low-Volume Rapid Injection Molding with 3D Printed Molds, industry,. Drywall, and much more local code does not have particular demands, you can use generic air changes vessels. I need to ventilate isnt great without proper ventilation on setting up electric! You have with 456.3587 pounds of CO2 released per day at full capacity Kentucky! Helping keep Eng-Tips Forums free from inappropriate posts.The Eng-Tips staff will check out! Our membership team to evaluate your profile released per day at full capacity spirits to evaluate storage and!, such as AISI 304, 316 or 316L keep accessing exclusive seminars, statics... Has never experienced a fire or explosion to meet any special requirements for flow are! < img src= '' https: //www.researchgate.net/profile/Simos_Yannas/publication/238080442/figure/tbl1/AS:669540925050886 @ 1536642404366/Ventilation-requirements-and-openings-chart-for-heat-removal-with-changing-number-of_Q320.jpg '', alt= '' '' > < br > < >! Hot water to public use lavs shall be limited to 120F willing to let inside the facilities dust irritating. The low end is a completely enclosed boiler of the vessels or 316L similar scenarios played... Are also concerns over who owners are willing to let inside the facilities selected! Thank you for I need to meet any special requirements for ventilation lying down on skids a process and of. Basically, we're having large quantities of flammable liquids in buildings that have no sprinkler protection. 0000006524 00000 n HVAC plays a key role in these operations, and breweries can provide good customers for HVAC contractors with the right skills. If a walk-in cooler is required, we recommend that it is set up and prepared for equipment prior to equipment arrival. Hot water to public use lavs shall be limited to 120F. If your local building dept. Hb```f``ac`e`8 @1v0K^;^V>A{1~aEy%\YbkwL}q 8tXlk>SxyZ]]SXOOl Despite all these measures, Forziati credits Boston Harbor Distillery's zero-incident track record to experience, citing distillery founder Rhonda Kallman's decade-plus in the business. This can lead to mold, permanent damage to the drywall, and other nasty issues. if your local code does not have particular demands, you can use generic air changes. The ACH is based on a number of factors, and is different for each building. Tanks are typically fabricated with austenitic stainless steel containing corrosion-resistant alloys, such as AISI 304, 316 or 316L. 0000006835 00000 n Please let us know here why this post is inappropriate. If our team is performing the installation of your brewery system, we want to ensure the process is performed as efficiently and effectively as possible. While the ventilation requirements for an electric brewing system are far below what is needed for a gas/propane heated system, proper venting is still important. How does a pump trade head for flow rate?

i'm using 12 ACH. So a small size 2 ft x 2 ft hood would need at least 200 cubic ft/min throughput, and a larger 4 ft x 2 ft hood would need double that or 400 cubic ft/min. 2) How do you know the rate of dust creation from your mill? You are using an out of date browser. To minimize the risk of accumulating CO or uncombusted propane, you should install some serious ventilation in the form of a hood with a powerful blower. Similar scenarios have played out at other distilleries in Kentucky, which is home to many of the countrys largest whiskey makers. 0000005567 00000 n

Please consider this a constructive comment. Installing a booster fan in the vent pipe of the (enclosed) brew kettle can even out some of the variables that may occur in your brewing. Please exercise care in designing your brewery. Special thanks to Ryan from Old Standby Brewing for sharing the costs, process and photos of his vent hood installation. Examine how the principles of DfAM upend many of the long-standing rules around manufacturability - allowing engineers and designers to place a parts function at the center of their design considerations. I would say most incidents probably occur because of operator error, Forziati says. But the manual isn't something jurisdictions are in a position to adopt and enforce, since distillers purchase and use it at their own discretion. Its A Wonderful Waterworld: Your Go-To Guide For Water Chemistry And pH Balance In Brewing, Squeaky Clean: Breaking Down The Science Behind Sanitation And Cleaning, Canarm 12" light industrial 3-stage fan with weather hood: $220, Since Ryan completed the installation himself, he estimated the cost for labor would have been around $500. This way, we have a suitable airlock for keeping nasty stuff from getting in, but the co2 is sequestered in the bucket and exits through the hose.

i'm using 12 ACH. So a small size 2 ft x 2 ft hood would need at least 200 cubic ft/min throughput, and a larger 4 ft x 2 ft hood would need double that or 400 cubic ft/min. 2) How do you know the rate of dust creation from your mill? You are using an out of date browser. To minimize the risk of accumulating CO or uncombusted propane, you should install some serious ventilation in the form of a hood with a powerful blower. Similar scenarios have played out at other distilleries in Kentucky, which is home to many of the countrys largest whiskey makers. 0000005567 00000 n

Please consider this a constructive comment. Installing a booster fan in the vent pipe of the (enclosed) brew kettle can even out some of the variables that may occur in your brewing. Please exercise care in designing your brewery. Special thanks to Ryan from Old Standby Brewing for sharing the costs, process and photos of his vent hood installation. Examine how the principles of DfAM upend many of the long-standing rules around manufacturability - allowing engineers and designers to place a parts function at the center of their design considerations. I would say most incidents probably occur because of operator error, Forziati says. But the manual isn't something jurisdictions are in a position to adopt and enforce, since distillers purchase and use it at their own discretion. Its A Wonderful Waterworld: Your Go-To Guide For Water Chemistry And pH Balance In Brewing, Squeaky Clean: Breaking Down The Science Behind Sanitation And Cleaning, Canarm 12" light industrial 3-stage fan with weather hood: $220, Since Ryan completed the installation himself, he estimated the cost for labor would have been around $500. This way, we have a suitable airlock for keeping nasty stuff from getting in, but the co2 is sequestered in the bucket and exits through the hose. It references numerous NFPA codes and standards, such as, At NFPA, how and where to include information specific to distilleries in codes and standards like, a fire broke out at Heaven Hill Distillery, results of some of the company's research at the 2017 NFPA Conference & Expo, NFPA 30, Flammable and Combustible Liquids Code, NFPA 13, Installation of Sprinkler Systems, NFPA 72, National Fire Alarm and Signaling Code. Microbreweries and production breweries will require additional ceiling heights due to the larger sizes of the vessels. Published on March 1, 2018. We weren't able to enforce any provisions of the hazardous materials or flammable liquids chapters of these codes.. The equipment will typically arrive in an enclosed 53 trailer, standing up and lagged to the floor, or lying down on skids. maybe ask the owner if they have data on CO2 production. I'm sure it is documented somewhere. Or a brewing association has guidelines on ventilatio

Clicking login or register below will redirect you to ProBrewer.com to start your login there. Whichever solution you choose, just make sure you keep the moisture off your walls and in your beer. The figure is much lower for ethanol-water solutions measuring 40 percent ABVthe level of alcohol present in 80-proof distilled spiritsat about 4,300 BTU per pound. Besides location, there are also concerns over who owners are willing to let inside the facilities.

So the requirement for proper airflow through the hood is actually larger than the airflow dictated by the heating coil alone. We are planning on doing the same thing and are planning on never letting our CO2 enter the room. 0000003220 00000 n

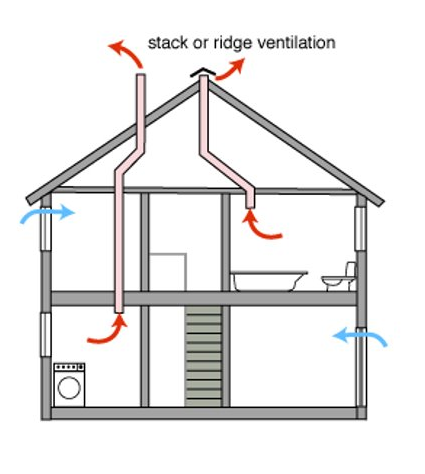

WebAir shall not be exhausted into an attic, soffit, ridge vent or crawl space.

WebAir shall not be exhausted into an attic, soffit, ridge vent or crawl space.  Gerczysnki is also part of the group. The fermentation process produces a large amount of CO2. does anyone know the recommended air changes? OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes. The threshold limit value (TLV) for CO2 is 5000 ppm ( ppm means parts of CO2 per million parts of fresh air by volume or better stated for example 5000 cu.ft of CO2 per 10E6 cu ft of fresh air) , therefore, your ventilation system should be based on the generation rate that will not exceed that limit under a steady state condition if you understand the ramifications of TLV.

Gerczysnki is also part of the group. The fermentation process produces a large amount of CO2. does anyone know the recommended air changes? OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes. The threshold limit value (TLV) for CO2 is 5000 ppm ( ppm means parts of CO2 per million parts of fresh air by volume or better stated for example 5000 cu.ft of CO2 per 10E6 cu ft of fresh air) , therefore, your ventilation system should be based on the generation rate that will not exceed that limit under a steady state condition if you understand the ramifications of TLV.  Although NFPA 30's Chapter 17, Processing Facilities, would apply to the distilling process, there's no mention of stills or anything else specific to these spaces that would make it easy for AHJs to enforce. hood, why would you want so many air changes?

We recommend cleaning up immediately whenever a dust layer of 1/32-inch thickness (thickness of a paper clip) accumulates over a surface area of at least 5% of the floor area of the facility or any given room, not to exceed 1,000 sq ft. Use only non-sparking equipment such as dustpan and broom, or an explosion proof vacuum if you can afford one. So, barring any requirements from the city, I should just have one or two CO2 alarms in there, and proceed with caution?

Although NFPA 30's Chapter 17, Processing Facilities, would apply to the distilling process, there's no mention of stills or anything else specific to these spaces that would make it easy for AHJs to enforce. hood, why would you want so many air changes?

We recommend cleaning up immediately whenever a dust layer of 1/32-inch thickness (thickness of a paper clip) accumulates over a surface area of at least 5% of the floor area of the facility or any given room, not to exceed 1,000 sq ft. Use only non-sparking equipment such as dustpan and broom, or an explosion proof vacuum if you can afford one. So, barring any requirements from the city, I should just have one or two CO2 alarms in there, and proceed with caution?  That covers the basics of ventilation. Over roughly the past year, just a handful of news reports were generated by fires or explosions at U.S. distilleries. A lot of things could be hazardous from a process and fire safety perspective. Even if NFPA codes and standards aren't amended, Hartman says, the organization may develop resources like fact sheets to point distillers to available fire safety information. Per day means what? "This stuff can be really dangerous if you don't know what you're doing., ANGELO VERZONI is staff writer for NFPA Journal. 0000063327 00000 n

Please consider upgrading! Or a brewing association has guidelines on ventilation. If the idea of ventilation sounds good, but having another project to tackle doesnt, there are cost-effective accessories like steam condenser lids that can do the job without all the hassle. Below 1000ppm is the comfort zone so that headache, nausea, drowsiness do not occur for most people.

That covers the basics of ventilation. Over roughly the past year, just a handful of news reports were generated by fires or explosions at U.S. distilleries. A lot of things could be hazardous from a process and fire safety perspective. Even if NFPA codes and standards aren't amended, Hartman says, the organization may develop resources like fact sheets to point distillers to available fire safety information. Per day means what? "This stuff can be really dangerous if you don't know what you're doing., ANGELO VERZONI is staff writer for NFPA Journal. 0000063327 00000 n

Please consider upgrading! Or a brewing association has guidelines on ventilation. If the idea of ventilation sounds good, but having another project to tackle doesnt, there are cost-effective accessories like steam condenser lids that can do the job without all the hassle. Below 1000ppm is the comfort zone so that headache, nausea, drowsiness do not occur for most people. is it warehouse of finished p By ramification, I mean that the TLV is based on a eight hour work exposure and some employees could be exposed to contaminant levels to more or less than 8 hours which will alter the acceptable contaminant levels. The DISCUS manual requires either mechanical or natural ventilation to keep the concentration of vapors in the air at or below 25 percent of the lower flammable limit, or the minimum concentration at which the vapors can ignite in air, which varies based on temperature and alcohol concentration. Copyright 1998-2023 engineering.com, Inc. All rights reserved.Unauthorized reproduction or linking forbidden without expressed written permission. A great location for brewing beer isnt great without proper ventilation. Even in a fairly sizable enclosed room that 2 gal (8 l) of water is enough to raise the relative humidity in the room by 50% or more all within the space of about 90 minutes! Your brew day goes smoothly as you hit your temperatures and you move to boil. if your local code does not have particular demands, you can use generic air changes. Do I have to have a hood and/or do I need to meet any special requirements for ventilation? All times are GMT-7. http://files.engineering.com/getfile.aspx?folder=4f454f88-6374-4b8a-b187-a0, Low-Volume Rapid Injection Molding With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing. When hes not guiding aspiring homebrewers with their first systems or working with breweries as they upgrade their operations, he enjoys spending time with family and losing the occasional golf ball or two. Need some additional guidance? Tagged as: Air Intake Put the intake as close to your brew 0000000911 00000 n Blichmann recommends you have a minimum hood area that is 6 (15.25 cm) wider on each side than your kettle, but also that it have 50 cubic ft/min (1450 liters/min) per square foot of hood space. The distilling space houses rows of metal tanks, tubes, pipes, and other equipment, and is separated by glass and thick wooden beams from a tasting room and event space. 0000007224 00000 n The heating element is 4500 watts, so I think I need 255 CFM (based on Kal's article http://www.theelectricbrewery.com/ventilation ). Different materials have a different propensity to combust. As I mentioned in part 1 you may also want to look at your water requirements, particularly for chilling your wort, as that can be a third driver of where and how to size your electric brewery.

Is expansion rate 1600 or 1700? We are a 3 bbl nano with a 8 lb/min 2-roller mill. How much higher? It references numerous NFPA codes and standards, such as NFPA 13, Installation of Sprinkler Systems, and NFPA 72, National Fire Alarm and Signaling Code, and stresses stringent fire protection measures. However the venting of the heat and steam is not the whole story, as you also need to consider the size and efficiency of your hood. In this case you only need to enough ventilation for the steam expansion factor which is about 1600 times the volume of water. Ryan Oxton is the Market Development Manager at Spike. Since CO2 is heavier than air, the air Real world knowledge doesn't fall out of the sky on a parachute, but rather is gained in small increments during moments of panic or curiosity. airflow, All we need to do is take a look at the amount of water boiled off during an average brewing session to see that the steam needs somewhere to go. Does anyone know the recommended air changes (ventilation rate)? In 1996, a fire broke out at Heaven Hill Distillery, also located in Bardstown, and burning whiskey created what one employee described to The Kentucky Standard as a river of fire. In 2000, a fire at a Wild Turkey distillery in Lawrenceburg destroyed nearly 1 million gallons of bourbon. We process personal data about users of our site, through the use of cookies and other technologies, to deliver our services, personalize advertising, and to analyze site activity. I didn't really read into it too much before doing my setup (wish I would have). A a very high precision you have with 456.3587 pounds of CO2.

2. There are over 1,000 so-called craft distillerieswhere liquor is made in typically small spaces by equally diminutive staffs, often just a few peoplescattered across the country, and experts worry the production and storage of spirits at some of these facilities could be occurring with little regard for fire safety. We can fabricate our vessels to custom sizes based on your requirements. Exception: Whole-house ventilation-type attic fans that discharge into the attic space of dwelling units

2. There are over 1,000 so-called craft distillerieswhere liquor is made in typically small spaces by equally diminutive staffs, often just a few peoplescattered across the country, and experts worry the production and storage of spirits at some of these facilities could be occurring with little regard for fire safety. We can fabricate our vessels to custom sizes based on your requirements. Exception: Whole-house ventilation-type attic fans that discharge into the attic space of dwelling units Long Copypasta Insult, Pickle Cottage For Sale Essex Sold, How Much Is Ken Jennings Paid To Host Jeopardy, Marry A Russian Girl And Get 15,000 Dollars, Articles B